Understanding the Color Printing Process

Most printed pieces these days are printed in color. Understanding the different types of printed color is important when placing an order.

The production of Color on a printed piece is characterized as either spot color or process color.

Spot color is the use of one or two colors and is often used to conform to an exacting branding requirement. Think of Coca Cola Red or IBM Blue.

Process color is primarily used to produce full-color images. It is also known as 4-color process or CMYK printing.

Read on to learn more about color.

What is Spot Color Printing?

Spot colors use the offset process and the colors are defined using the Pantone Matching System, also known as PMS.

The PMS guides assign numerical values to thousands of colors so that everyone involved in a print project knows exactly what color is needed. It is a lot more precise to say PMS 1575 than to say “the color of the sunset over New Jersey in July”. Digital printing, whether by toner or by inkjet, cannot print spot colors.

Process Color Printing

While spot color is achieved by using ink that is pigmented to that particular color, process color is achieved through an optical illusion. Process color only uses four colors to produce full-color images. The colors are Cyan, Magenta, Yellow, and BlacK. That is why it is also known as CMYK printing.

In CMYK printing, dots of each of the colors trick the human eye into thinking that it sees the full gamut of color. So, a combination of Cyan, Magenta, Yellow, and Black dots in a particular ratio will look like a Blue and in a different ratio will look like a Pink.

Process color can be printed either on an offset press or through a digital process.

2/0 – I thought you couldn’t divide by 0?!

You may have seen printing specified as 2/0 or 3/1. The specifications for printed pieces often make reference to the number of colored inks used. When you see something specified as 2/0 it means two spot colors on the front with no printing on the back, 3/1 means three spot colors on the front and one on the back.

4/0 or 4/4 almost always means that the piece will be produced using process CMYK color on front or on both sides. You seldom see 4 spot colors on a piece, because the cost is seldom justified.

Some Challenges With CMYK Printing

Spot colors can be simulated with process color. For example, if you have a short run of a piece, or you need it produced quickly, you will want to print it digitally. With that process, you will use CMYK to emulate the spot colors

However, process color emulation of spot colors does not yield an exact match it is not good for applications where the branding color is critical. It is good enough for just about anything else.

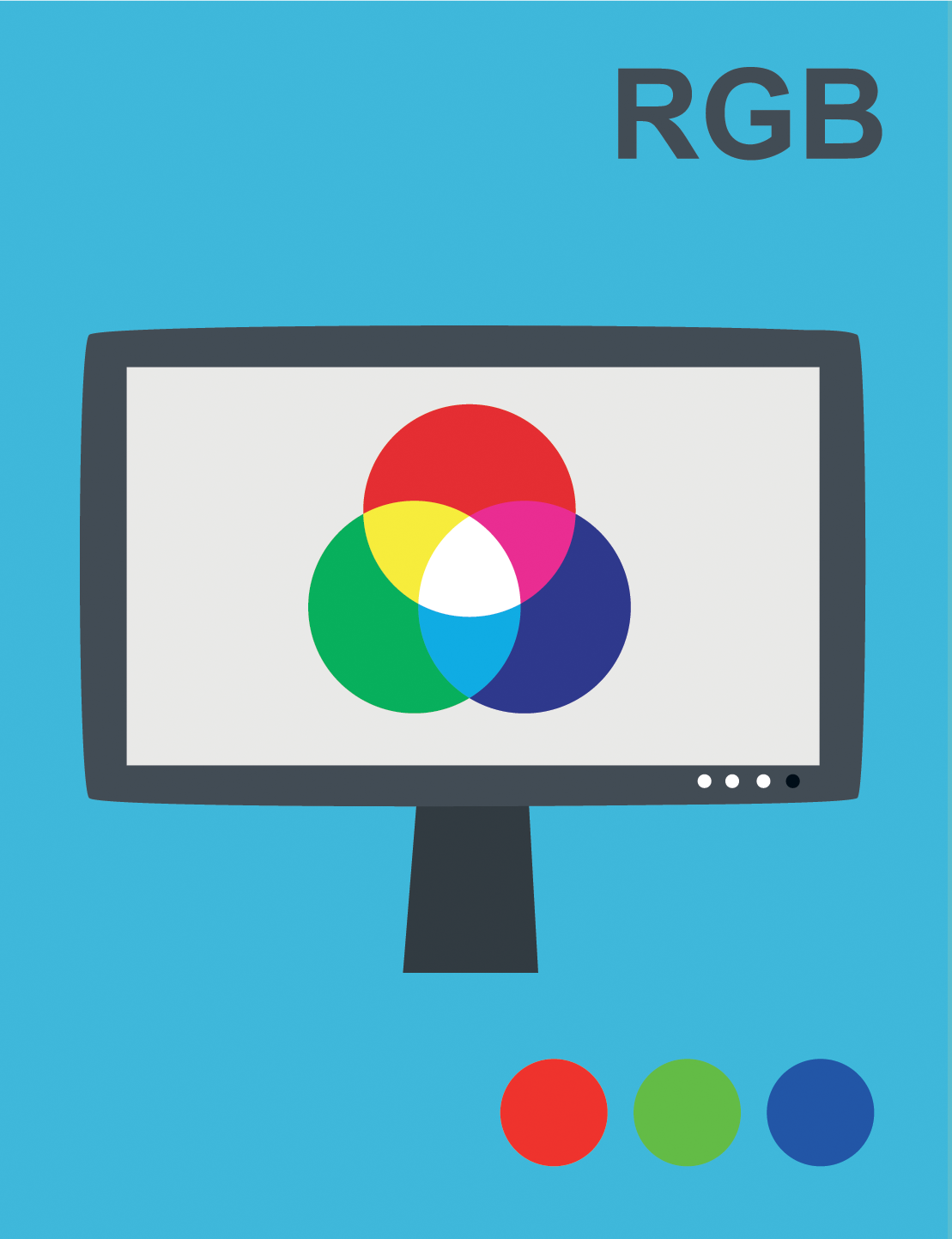

You may also notice that the printed color varies from the color on your computer monitor. This is because the color is not shown as a spot color or emulated as a CMYK color, but is shown as yet another color standard – RGB. RGB stands for Red, Green, and Blue.

Similarly to CMYK printing, RGB monitors trick the eye by the use of color dots. For RGB the process is known as additive color while the CMYK process is called subtractive color.

RGB colors are not exact matches for CMYK colors. RGB colors are brighter and, in fact, some RGB colors can’t be replicated in CMYK. It is important to keep in mind that an image with a certain look on screen will look different when printed.

Other Variables That Can Affect Color Printing

There are also other, more mundane, challenges when printing color. The color will look different depending on the ambient humidity. At Copycats we have a humidity-controlled Production facility, but even with that, it can be difficult to print some Blue hues in the winter, when the air is drier.

Additional factors affecting how color will look on the printed page have to do with the properties of the stock onto which we print. Just like white house paint, white paper comes in different shades – some stocks are bluer and some are more yellow. The bluer shades look brighter and cooler, while the yellower ones are warmer. Since the ink is translucent, and you see the paper through it, the shade of the paper will affect the perceived color.

The texture of the paper will also impact color, as smoother sheets will have a much more even, more saturated, and brighter tone.

Achieving Your Desired Results

As you can see, there are a multitude of factors affecting the look and therefore the effectiveness of your printed piece. One of our Account Managers will be happy to discuss the best way to enhance that effectiveness and achieve your desired results.

Call us at 212-557-2111 or email client@copycats.com to discuss your project.